K-series problem

There are two main head gasket complaints:

• The first is water in the oil;

This is usually to do with the red neoprene sealer that is attached to the gasket – this is damaged very easily.

Early manufactured gaskets had this sealer lightly bonded to the surface of the gasket and was prone to just coming detached by any gentle contact.

Later, gaskets were improved by bonding the sealer together through holes in the gasket. This stopped the sealer scraping off but is still prone to ‘nicks’ if not being fitted with absolute care.

Landrover do offer an alternative multi-layered steel head gasket with no neoprene sealer but this offers little advantage other than you can be a bit rougher when handling and fitting it.

• Cooling system pressurization leading to overheating.

There is a combination of two factors causing this problem.

One is that the head gasket comprises of a very narrow combustion fire ring (only 1.5mm) which seals the combustion chamber pressure from the cooling system.

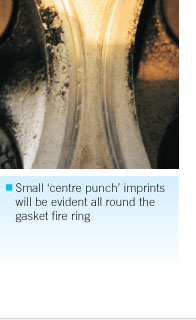

The other is the fact that the aluminium used to cast the heads was not pure. This leaves tiny cavities within the whole casting often showing up on the head as black ‘fleck’ marks and where the combustion fire ring has been in contact with the face, small ‘centre punch’ imprints will be evident all round. Each one of these imprints is a potential gasket failure point.

If the gasket fails and the engine overheats, the casting softens allowing deep circular imprints or grooves to be made in the head face where it contacts the gasket fire ring.